12 – Reduction of residual stress effects – part design, mold construction, machine settings

12 – Reduction of residual stress effects – part design, mold construction, machine settings

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

Residual stresses are mechanical, residual stresses generated by internal forces in the injection-molded part during the injection molding cycle.

In this webinar, we will show how to reduce the effects of residual stress manifested as part deformation after ejection.

One option is to modify the part shape to increase its stiffness against internal forces.

Another option is to adjust injection parameters to reduce the magnitude of internal forces.

Similarly, we can reduce internal forces through mold design—by designing the gating and cooling systems.

Another way to reduce deformation is local correction of the mold cavity shape with an opposite deformation.

In this webinar, we will show how to reduce the effects of residual stress manifested as part deformation after ejection.

One option is to modify the part shape to increase its stiffness against internal forces.

Another option is to adjust injection parameters to reduce the magnitude of internal forces.

Similarly, we can reduce internal forces through mold design—by designing the gating and cooling systems.

Another way to reduce deformation is local correction of the mold cavity shape with an opposite deformation.

Program

Reducing the effects of residual stress by modifying the shape of injection-molded parts

Basic principles of proper technological design

Reducing the effects of residual stress by adjusting injection molding parameters

Reducing the effects of residual stress through injection mold design

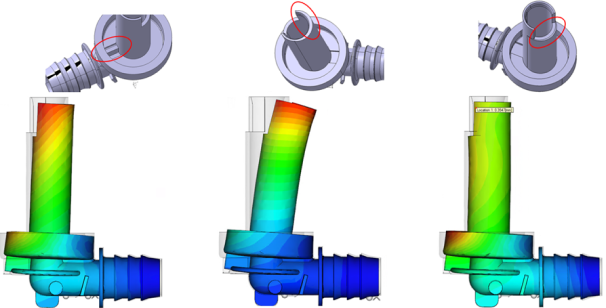

Placement and number of gate entrances

Cooling circuit regulation – flow rate, temperature

Parallel and series cooling

Mold cavity shape correction by opposite deformation

Webinar

12 – Reduction of residual stress effects – part design, mold construction, machine settings

Presenter

Ing. Petr Halaška