9 – Design conflicts between part and mold, how to further optimize cooling

9 – Design conflicts between part and mold, how to further optimize cooling

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

The cost of plastic and cooling time can account for more than 70% of the part production costs.

In webinar No. 8, we described how cooling time is influenced by part wall thickness, type of plastic and filler, mold material, and identification of areas with difficult heat dissipation.

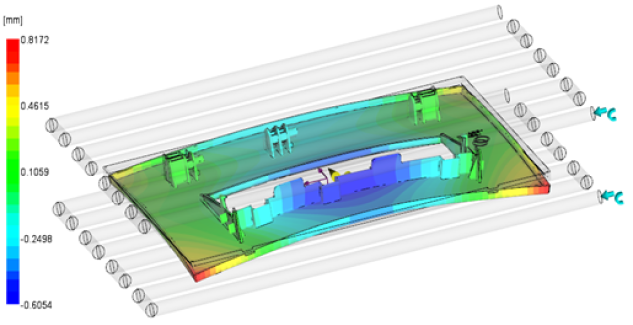

In this webinar, we will show the conflict between advanced part design and mold construction possibilities. How part design can affect cooling time and mold stiffness.

We will also show what else can influence cooling time and optimization.

In webinar No. 8, we described how cooling time is influenced by part wall thickness, type of plastic and filler, mold material, and identification of areas with difficult heat dissipation.

In this webinar, we will show the conflict between advanced part design and mold construction possibilities. How part design can affect cooling time and mold stiffness.

We will also show what else can influence cooling time and optimization.

Program

Conflict between technological part design and mold design

Effect of the type of tempering medium on cooling time

How does the flow of the tempering medium in the cooling system affect cooling efficiency

Effect of the distribution of tempering channels on the stability of the temperature field

Effect of mold temperature, melt temperature, and demolding temperature on cooling time

How does mold temperature affect part quality

Webinar

9 – Design conflicts between part and mold, how to further optimize cooling

Presenter

Ing. Petr Halaška