8 – Cooling – part design – mold construction – mold maintenance

8 – Cooling – part design – mold construction – mold maintenance

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

The cost of plastic and cooling time can account for more than 70% of the part production costs.

Cooling time represents the longest part of the injection cycle. It mainly depends on part design, set injection parameters, and cooling efficiency.

In this webinar, we will show some steps to shorten the cooling time. We will complete the last part of the previous webinar about the actual behavior of injection-molded plastic parts in relation to the tolerance range.

We will demonstrate shrinkage calculation in Moldflow using CRIMS data.

Cooling time represents the longest part of the injection cycle. It mainly depends on part design, set injection parameters, and cooling efficiency.

In this webinar, we will show some steps to shorten the cooling time. We will complete the last part of the previous webinar about the actual behavior of injection-molded plastic parts in relation to the tolerance range.

We will demonstrate shrinkage calculation in Moldflow using CRIMS data.

Program

How does the plastic affect cooling time (type, filler)?

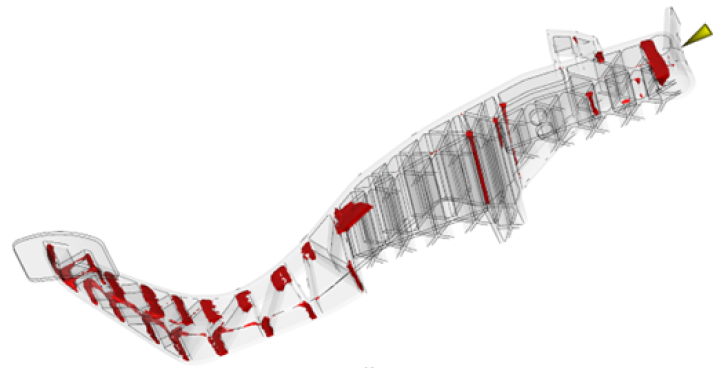

What is the actual wall thickness of the part and how does it affect cooling time?

Effect of mold material on cooling in areas with difficult heat dissipation (hardened steel, tool steel, Ampco)

Determination of tolerance zone

CRIMS data in Moldflow – optimization of injection-molded part shrinkage

Webinar

8 – Cooling – part design – mold construction – mold maintenance

Presenter

Ing. Petr Halaška