3 – Cavity filling instability, rheology, shear stress, accuracy of Moldflow results, uneven cavity filling

3 – Cavity filling instability, rheology, shear stress, accuracy of Moldflow results, uneven cavity filling

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

How accurate are Moldflow analysis results? The results are only as accurate as the input data. In this webinar, the data are rheological. We will discuss how measuring flow properties affects the accuracy of cavity filling analysis.

We will show an analysis of shear stress on the part wall and how it impacts the part’s durability. Similarly, we will examine shear rate, identifying critical points for its exceedance during the injection process. How to analyze polymer damage caused by shear stress will also be covered.

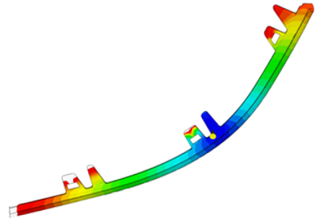

Very often, injection-molded parts have thin walls that are difficult to fill. We will demonstrate the influence of cavity pressure on their filling.

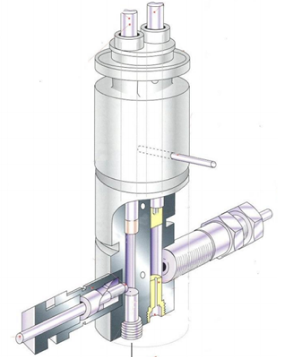

Cores in the mold can deform due to melt pressure during filling. We will answer how to analyze deformation and changes in wall thickness.

Finally, we will describe the jetting effect (free flow), how it arises, and how to eliminate this phenomenon.

This webinar is also suitable for users of analytical software other than Moldflow.

We will show an analysis of shear stress on the part wall and how it impacts the part’s durability. Similarly, we will examine shear rate, identifying critical points for its exceedance during the injection process. How to analyze polymer damage caused by shear stress will also be covered.

Very often, injection-molded parts have thin walls that are difficult to fill. We will demonstrate the influence of cavity pressure on their filling.

Cores in the mold can deform due to melt pressure during filling. We will answer how to analyze deformation and changes in wall thickness.

Finally, we will describe the jetting effect (free flow), how it arises, and how to eliminate this phenomenon.

This webinar is also suitable for users of analytical software other than Moldflow.

Program

Rheological properties of plastics – temperature, velocity, pressure, wall slip

What does the accuracy of Moldflow cavity filling analysis depend on?

Shear stress on the wall, how it affects the lifecycle of the injection-molded part

Shear rate, critical points in the injection molding process

How to analyze polymer damaged by high shear rate?

Uneven filling of varying wall thicknesses in the cavity

How does air pressure in the cavity affect uneven filling?

Change in cavity wall thickness due to elastic deformation of the core

Formation, elimination, and analysis of the Moldflow jetting effect

Webinar

3 – Cavity filling instability, rheology, shear stress, accuracy of Moldflow results, uneven cavity filling

Presenter

Ing. Petr Halaška