2 – Injection instability during cavity filling: orientation, cold welds, trapped air

2 – Injection instability during cavity filling: orientation, cold welds, trapped air

Domů / 2 – Injection instability during cavity filling: orientation, cold welds, trapped air

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

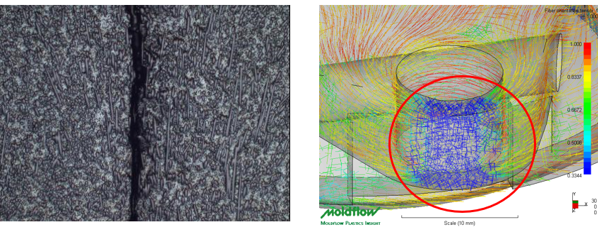

In this section, we will focus on injection instabilities that arise during the cavity filling phase, which stem from the nature of the plastic melt. During fountain flow of the melt, orientation of macromolecular chains in the flow direction, shear stress on the melt, and the melt front compresses air in the mold cavity, leading to the formation of a cold weld line.

Program

Fountain flow and its instabilities

Orientation of the macromolecular structure of polymers

What are flow lines and how do they form?

Orientation of fibrous filler, factors influencing it

Trapped air in the cavity, what it causes

How a cold weld, weld line, or melt line forms

What influences the cold weld problem

Webinar

2 – Injection instability during cavity filling: orientation, cold welds, trapped air

Presenter

Ing. Petr Halaška

Other webinars

🍪 It’s not the same without Cookies

Can we work with cookies to know how life is on our website?

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or solely for the purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistical

The technical storage or access that is used exclusively for statistical purposes.

Technické uložení nebo přístup, který se používá výhradně pro statistické účely.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.