1 – Injection instability – Rheology, plasticization, homogeneity, degradation, streaks

1 – Injection instability – Rheology, plasticization, homogeneity, degradation, streaks

Domů /

Presenter

Ing. Petr Halaška Smartplast s.r.o.

A frequently asked question is how accurate Moldflow analysis results are compared to reality. The answer is simple: The results are only as accurate as the input data. In this webinar, we will discuss how plasticization affects the quality of the injection-molded part and what visible defects may occur as a result. We will look at when these defects can be predicted and minimized using Moldflow. We will explain how precisely we can measure the melt temperature and pressure. This webinar is also suitable for users of other analytical software.

Program

Rheological properties of plastics – temperature, speed, pressure, wall slip

Melt temperature – do we know its value?

Melt residence time in the plasticizing unit

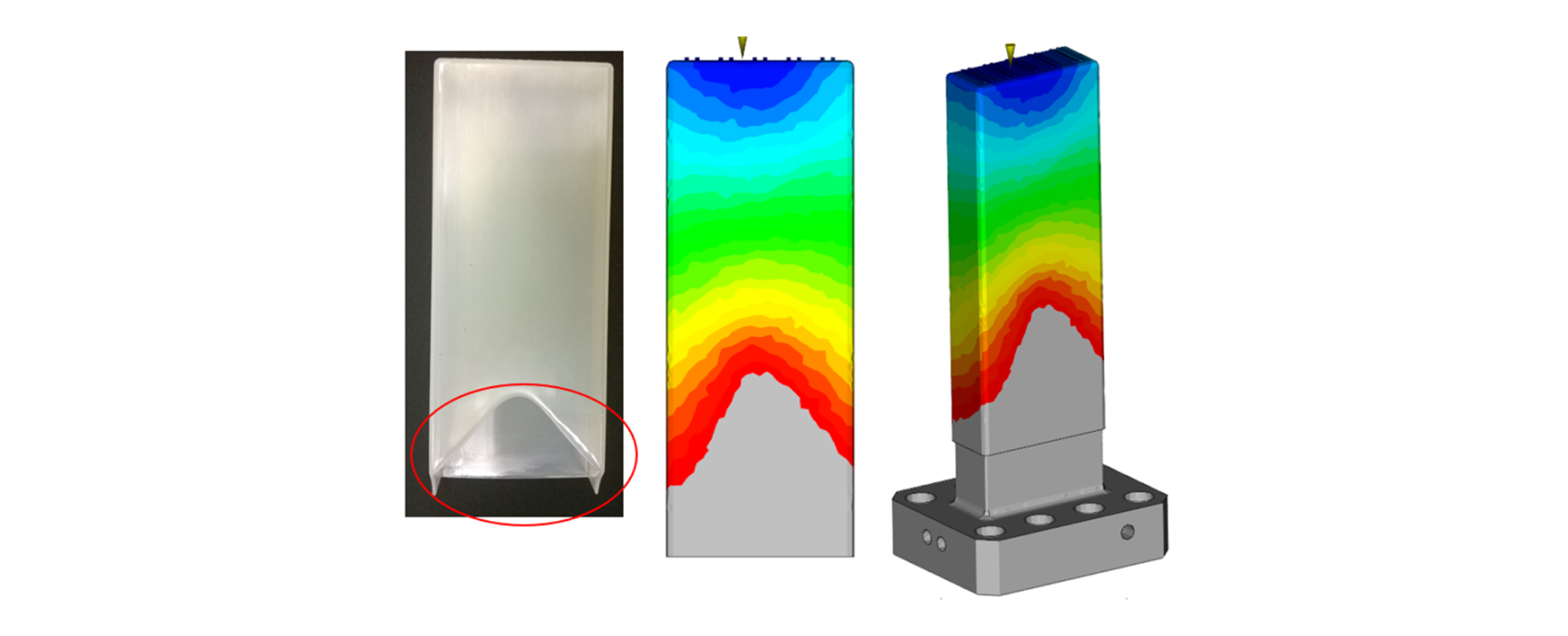

Inhomogeneities during plasticization, streaks on the molded part

Measurement of melt temperature and pressure

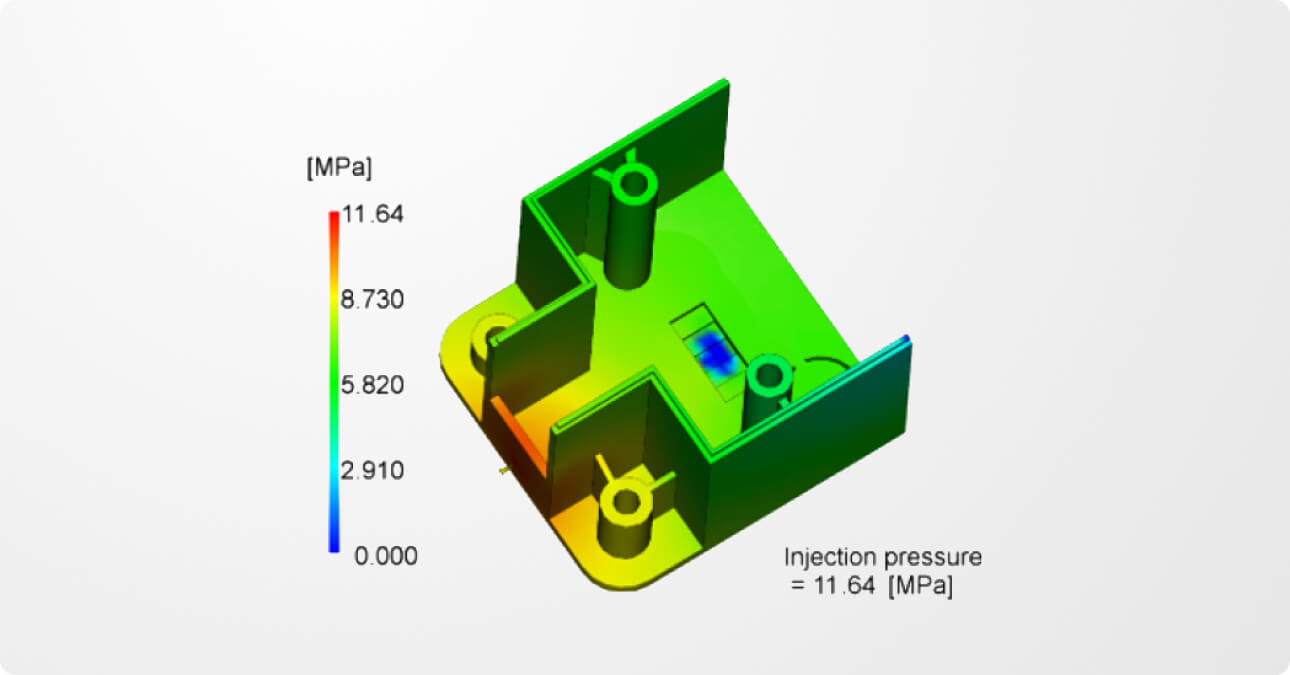

Accuracy of filling prediction in Moldflow

Effect of model geometry on pressure loss

Injection molding machine settings

Webinar

1 – Injection instability – Rheology, plasticization, homogeneity, degradation, streaks

Presenter

Ing. Petr Halaška

You can view the webinar recording here: