15 – Influence of part design and mold construction on cooling time

15 – Influence of part design and mold construction on cooling time

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

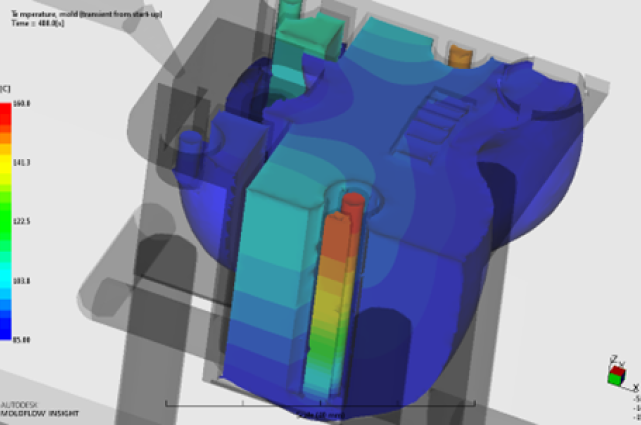

The cost of plastic and cooling time often make up more than 70% of the cost of manufacturing a part. Cooling time represents the longest part of the cycle. It depends on the part’s wall thickness, the type of plastic, melt temperature, mold temperature, mold material, cooling medium, flow, and the temperature of the part at ejection. These dependencies should be respected in the technological design of the part and the design of effective cooling in the mold, especially in areas with difficult heat dissipation. In this webinar, we will show some steps to achieve production cost reduction.

Program

How the choice of plastic affects cooling time

What exactly is the wall thickness of a part and how does it affect cooling time?

Which are the areas with difficult heat dissipation and how to identify them?

The influence of mold material on cooling of areas with difficult heat dissipation (hardened steel, tempered steel, Ampco)

Influence of mold material on mold stiffness

Conflict between good part design and mold construction in terms of cooling and stiffness (generative design, topology design)

Webinar

15 – Influence of part design and mold construction on cooling time

Presenter

Ing. Petr Halaška