11 – Effect of residual stress on deformation and part quality

11 – Effect of residual stress on deformation and part quality

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

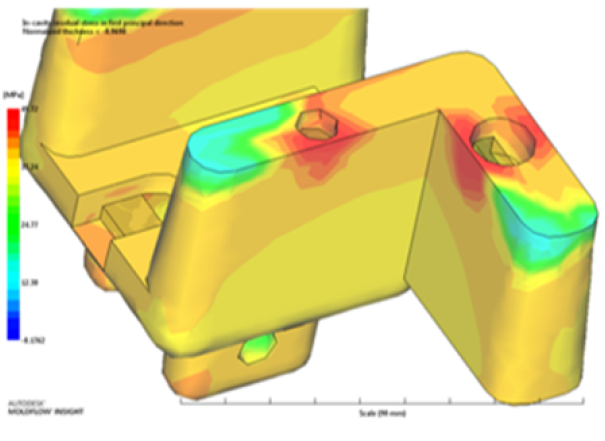

Residual stresses are mechanical, residual stresses generated in the injection-molded part during manufacturing. They remain embedded in the part even after ejection from the mold cavity and throughout the part’s lifecycle.

The presence and subsequent changes of residual stresses can significantly affect part durability, shape changes with ambient temperature and over time. These changes can also worsen the optical properties of injection-molded parts. Mold lifespan, especially of hardened molds, may depend on residual stress levels, which can also degrade part quality during subsequent operations (e.g., painting, welding).

The presence and subsequent changes of residual stresses can significantly affect part durability, shape changes with ambient temperature and over time. These changes can also worsen the optical properties of injection-molded parts. Mold lifespan, especially of hardened molds, may depend on residual stress levels, which can also degrade part quality during subsequent operations (e.g., painting, welding).

Program

What happens to residual stress after part ejection?

How does residual stress affect part stiffness?

How does residual stress affect the stiffness of a part with metal inserts?

Effect of residual stresses on mold stiffness

Effect of residual stresses on the optical properties of the part

Effect of residual stress on subsequent operations

Webinar

11 – Effect of residual stress on deformation and part quality

Presenter

Ing. Petr Halaška