6 – Injection inhomogeneities during packing, sink marks, voids, air bubbles

6 – Injection inhomogeneities during packing, sink marks, voids, air bubbles

Domů /

Presenter

Ing. Petr Halaška

Smartplast s.r.o.

Smartplast s.r.o.

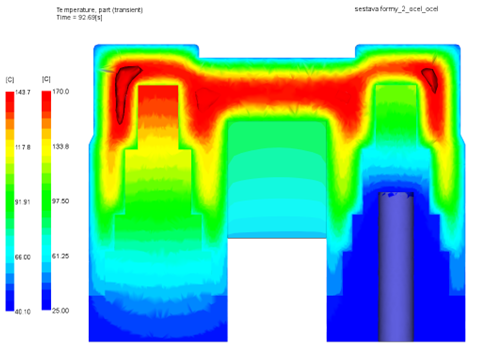

Sink marks are visible defects on the surfaces of injection-molded parts. A more severe stage are voids, unwanted cavities within the walls of injection-molded parts. They affect both the appearance and mechanical properties of the part. In this webinar, we will show how sink marks and voids form, and how to eliminate them through part design and mold design. We will also look at how sink marks and voids can be successfully predicted using Moldflow analysis to minimize the risk of their occurrence. This webinar is also suitable for users of other analytical software.

Program

What is a sink mark, how does it form?

What is a void, how does it form, difference between a void and an air bubble?

PVT diagram and the influence of plastic type on void formation

Moldflow prediction of void formation – technological part design

Moldflow prediction of void formation – mold design

CT tomography for scanning voids

Moldflow prediction of void formation – injection molding machine setup

Effect of voids on part strength

Webinar

6 – Injection inhomogeneities during packing, sink marks, voids, air bubbles

Presenter

Ing. Petr Halaška