Díl zapadá zpět do sestavy potrubí klimatizační jednotky.

Díl zapadá zpět do sestavy potrubí klimatizační jednotky.

Domů /

Firma

Valeo

umístění

Česká republika

Software

Autodesk® Moldflow®

Datum vydání

15.05.2025

Autodesk Moldflow pomáhá společnosti Valeo vyřešit deformaci dílu tak, aby zapadl do sestavy. Eliminace deformace dílu bez nutnosti výroby nové formy.

Valeo je globální dodavatel automobilového průmyslu se sídlem ve Francii, který poskytuje kompletní řadu produktů jak automobilkám, tak jejich dodavatelům. V České republice má Valeo pět závodů a výzkumně-vývojové centrum, kde vyvíjí a vyrábí klimatizační systémy, systémy recirkulace výfukových plynů, interiérové ovládací panely a čelní moduly, hydraulické ovladače spojek a brzd a ultrazvukové senzory.

V závodě v Rakovníku Valeo vyrábí klimatizační jednotky. Klimatizační jednotka se skládá z více než sta komponentů a je montována na 15 montážních linkách.

Proto je dobrý návrh každého dílu, který musí být vyrobitelný a zapadat do sestavy, zásadní.

„Díky simulacím Moldflow jsme dosáhli toho, že díl zapadl do sestavy, úpravy formy byly minimální a nebyl ohrožen termín zahájení výroby.“

Václav Chytrý

Manažer industrializace forem – Valeo

Problém

Problém se týkal součásti klimatizační jednotky, která již byla ve výrobě. Její deformace po vstřikování byla tak velká, že nezapadala do sestavy. Vstřikovací forma už byla vyrobena a nainstalována. Inženýři společnosti Valeo stáli před výzvou vyřešit deformaci dílu s využitím stávající formy a vyhnout se potřebě nové formy, zároveň však najít řešení, které by vyžadovalo minimální zásah a úpravy formy, aby nebyl ohrožen termín zahájení výroby projektu.

Řešení

Řešení se skládalo z několika kroků. Prvním krokem bylo popsat aktuální stav a identifikovat zdroj deformace pomocí analýzy Moldflow na základě kompletní výrobní dokumentace, včetně vstřikovacích parametrů, vtokového systému, systému temperace apod.

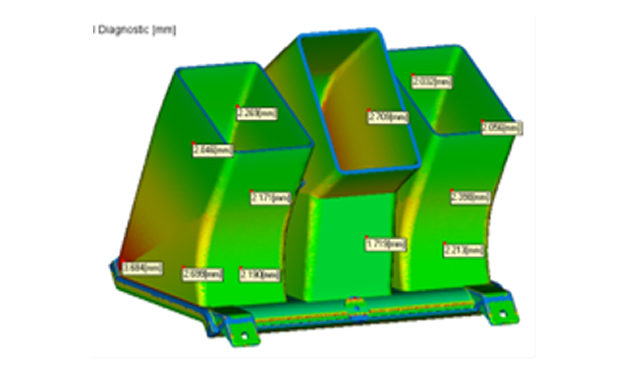

Analýza Moldflow odhalila několik příčin deformace, hlavními byly teplota formy a smrštění polymeru.

Bylo vypracováno šest konstrukčních návrhů řešení deformace, které byly ověřeny analýzou Moldflow.

Valeo si vybralo jeden z návrhů – upravit konstrukci dílu tak, aby vyžadovala minimální zásah do formy. Úprava spočívala ve vytvoření žeber na horní straně dílu, která fixují a následně minimalizují deformaci dílu.

Navržené řešení bylo pečlivě ověřeno pomocí analýzy Moldflow – předpovězená deformace dílu se oproti původnímu návrhu snížila o 50 %.

Přínos

Based on Moldflow simulations, the cause of the part deformation was identified and six methods to eliminate the deformation were proposed. Each variant was verified by Moldflow simulation and accompanied by commentary.

Valeo was able to make a qualified decision and validate it before modifying the mold. Using Moldflow simulation, Valeo precisely defined the problem and its cause, found a solution, selected the best design modification, and verified it. Solving the problem with Moldflow analyses took several days and cost thousands of euros. The cost of a new mold would have been tens of thousands of euros and its production would have taken months.

Závěr

Na základě simulací Moldflow byla identifikována příčina deformace dílu a navrženo šest způsobů, jak deformaci odstranit. Každá varianta byla ověřena simulací Moldflow a doplněna komentářem.

Valeo tak mohlo učinit kvalifikované rozhodnutí a ověřit jej ještě před úpravou formy. Pomocí simulace Moldflow Valeo přesně definovalo problém a jeho příčinu, našlo řešení, vybralo nejlepší konstrukční úpravu a ověřilo ji. Řešení problému pomocí analýz Moldflow trvalo několik dní a stálo tisíce eur. Náklady na novou formu by přitom byly v řádu desítek tisíc eur a její výroba by trvala měsíce.

„Díky Moldflow jsme mohli nasimulovat šest způsobů, jak odstranit deformaci, vybrat jeden na základě výsledků a ověřit dopad zvoleného řešení ještě předtím, než jsme sáhli na formu.“

Václav Chytrý

Manažer industrializace forem – Valeo

Potřebujete se dozvědět více? Kontaktujte nás.