Řešení deformace mřížky, navržené pro venkovní použití

Řešení deformace mřížky, navržené pro venkovní použití

Domů /

Firma

Čegan s.r.o.

Umístění

Česká republika

Software

Autodesk® Moldflow®

Datum vydání

15.05.2025

Problém

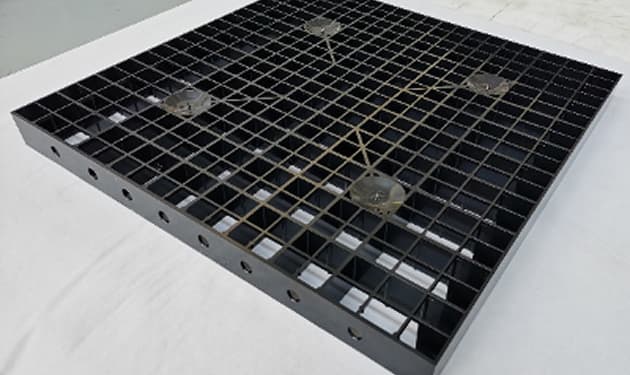

Jedním z vlastních produktů společnosti byl nosný prvek pro terasové systémy používané ve stavebnictví. Jedná se o mřížku z termoplastu, na kterou se pokládají dlaždice. Jednotlivé mřížky se spojují jako dlaždice do systému. Mřížka se přišroubuje na nosník, který je umístěn v libovolné výšce nad zemí v exteriéru. Požadavkem bylo, aby díl – mřížka – měl maximální tuhost a minimální deformaci, aby bylo možné mřížky spojovat do systému. Největší výzvou bylo minimalizovat deformaci dílu po vstřikování a zároveň dosáhnout maximální tuhosti pro odolnost vůči očekávanému zatížení.

Cíle projektu

Pro celý vývoj produktu i jeho výrobu byly stanoveny následující cíle:

- Navrhnout díl tak, aby se co nejvíce minimalizovalo riziko deformace.

- Maximalizovat tuhost dílu výběrem vhodného polymeru v kombinaci s technologickým návrhem dílu.

- Optimalizovat návrh dílu a vstřikovací formy, aby se minimalizovaly úpravy a dodatečné zásahy do formy.

- Zajistit bezproblémovou vyrobitelnost a montáž dílů.

„U našich vlastních produktů, kde máme volnou ruku v konstrukčních změnách, je simulace mnohem komplexnější a celkový návrh dílu se sleduje také z hlediska hmotnosti a mechanických vlastností. Při zahájení výroby formy je pak nutná nejen analýza vyrobitelnosti pomocí Moldflow, ale především pevnostní výpočty provedené simulací zatížení produktu v definovaných oblastech.“

Lukáš Zeman

Vedoucí oddělení kvality a technického oddělení

Řešení

Prvním úkolem bylo popsat aktuální stav návrhu dílu na základě základních dat, vstřikovacích parametrů a systémů vstřikování a temperace.

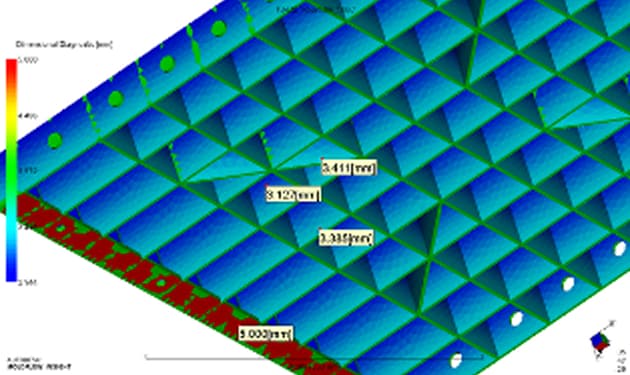

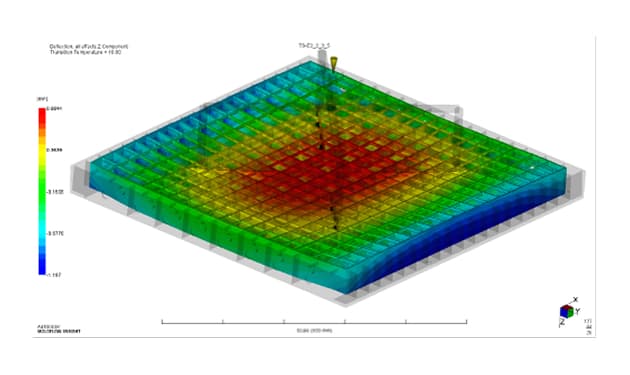

Ze simulace stávajícího návrhu dílu byly identifikovány výrobní rizika a očekávané chování dílu po vstřikování. Úvodní simulace předpověděly výraznou deformaci, konkrétně prohnutí dílu, které by značně komplikovalo montáž a funkci dlaždic mezi sebou. Úkolem bylo snížit riziko deformace úpravou dílu a formy. Zároveň musely konstrukční změny zajistit bezproblémovou výrobu s ohledem na celkový tvar dílu. Na základě výstupů ze simulací Moldflow byly navrženy varianty úprav vtokového systému, konstrukce dílu a procesních parametrů. Všechny konstrukční a procesní varianty byly ověřeny a porovnány prostřednictvím simulací Moldflow.

Čegan ze všech navržených variant zvolil kombinaci úprav konstrukce dílu, vtokového systému a systému temperace. Zvolená kombinace byla dále ověřena pevnostními výpočty, aby byla zajištěna stabilní výroba dílu a aby finální díl splňoval všechny požadavky.

Finální návrh dílu byl dále ověřen pevnostními výpočty pomocí softwaru Simulia Abaqus, který zohledňoval způsob a úroveň zatížení definovanou normami. Byla ověřena hodnota zatížení 7500 N/m², stejně jako uchycení dílu v sestavě a další okrajové podmínky, tj. podepření dílu, použitý polymer a materiálové charakteristiky polymeru při 23 °C a 60 °C. Úvodní konstrukční úpravy vykazovaly negativní výsledky pevnosti. Proto byly pevnostní kontroly průběžně prováděny souběžně s konstrukčními změnami, přičemž jednotlivé konstrukční úpravy byly vždy ověřeny také z hlediska pevnosti. Úloha byla řešena metodou Design of Experiment, kdy bylo provedeno více než 10 výpočetních iterací.

Přínos

Pomocí simulací Moldflow bylo popsáno budoucí chování dílu po výrobě a kritické oblasti z pohledu návrhu formy.

Z hlediska vyrobitelnosti bylo pomocí simulací Moldflow otestováno 8 variant úprav vtokového a temperačního systému a jejich vliv na finální díl. K dosažení nejlepších výsledků byly navíc zkoumány i úpravy samotného dílu.

- Proces řešení problému pomocí simulací Moldflow trval několik dní a stál stovky eur.

- Díky simulacím Moldflow jsme předešli budoucím problémům s formou a kvalitou dílu už ve fázi návrhu.

- Na hotové formě nebyly nutné žádné dodatečné úpravy, což snížilo náklady na zavedení dílu do výroby.

Závěr

Pomocí simulace Moldflow byla společnost Čegan schopna popsat budoucí chování dílu a úzká místa v návrhu vstřikovací formy. Všechna rizika byla vyřešena a odstraněna již ve fázi návrhu formy, před její výrobou. Veškeré ověřování dílu, nástroje a jejich úprav stálo jen zlomek času a nákladů ve srovnání s náklady spojenými s dodatečnými úpravami formy.

Potřebujete se dozvědět více? Kontaktujte nás.